Research and development

Salzgitter Mannesmann Forschung GmbH is the central research company of the Salzgitter Group. Employing about 300 members of staff active at 8 main departments at the Salzgitter and Duisburg locations, SZMF conducts extensive, in-depth research and development work revolving around the material steel.

Services of Salzgitter Mannesmann Forschung GmbH within the Initiative Automotive:

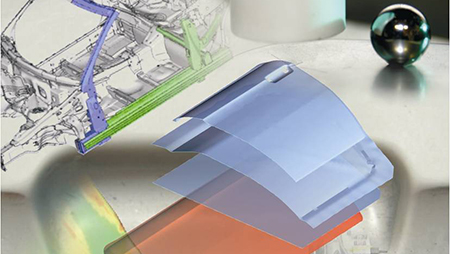

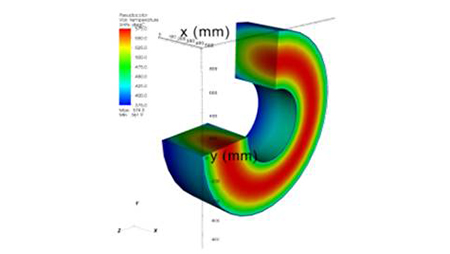

Engineering and simulation

- Analysis and prognosis regarding material trends

- Lightweight construction /resource efficiency studies

- Customer support (concept, FEM, prototypes, series production launch)

- Provision of FE material cards including new or optimized material characteristics for improved simulation quality

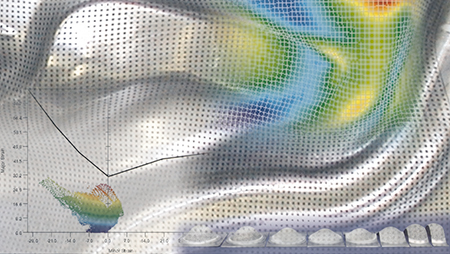

Metal forming

- Analysis and optimization of existing as well as conceptual design of new forming sequences and processes

- Materials characterization to describe the formability characteristics – from standardized test and inspection methods to component tests close to field conditions

- Development of new methods for expanded material description

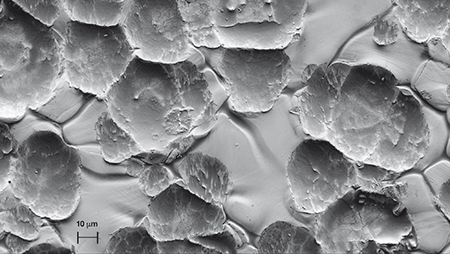

Surface Technology (ESO)

Customer-specific development of metallic and organic surface coating systems

Chemical surface treatment

- Development of powerful, in-process analysis methods for chemical surface treatments

- Evaluation of the corrosion and weathering performance using standardized or customer-specific testing

- Analysis of failure cases regarding corrosion of coated metallic materials and coating damage

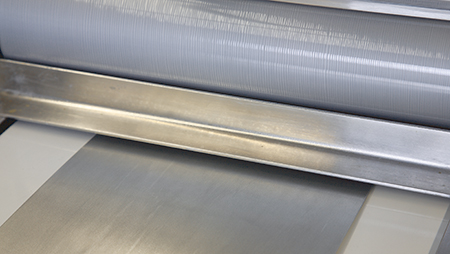

Metallic coatings

- Development and introduction of new coating systems, e.g., for the automotive, household appliance and construction industries (see StronSal®MC)

- Consultancy for customers on the use of coated products

- Development of strategy for applications, corrosion protection and processing